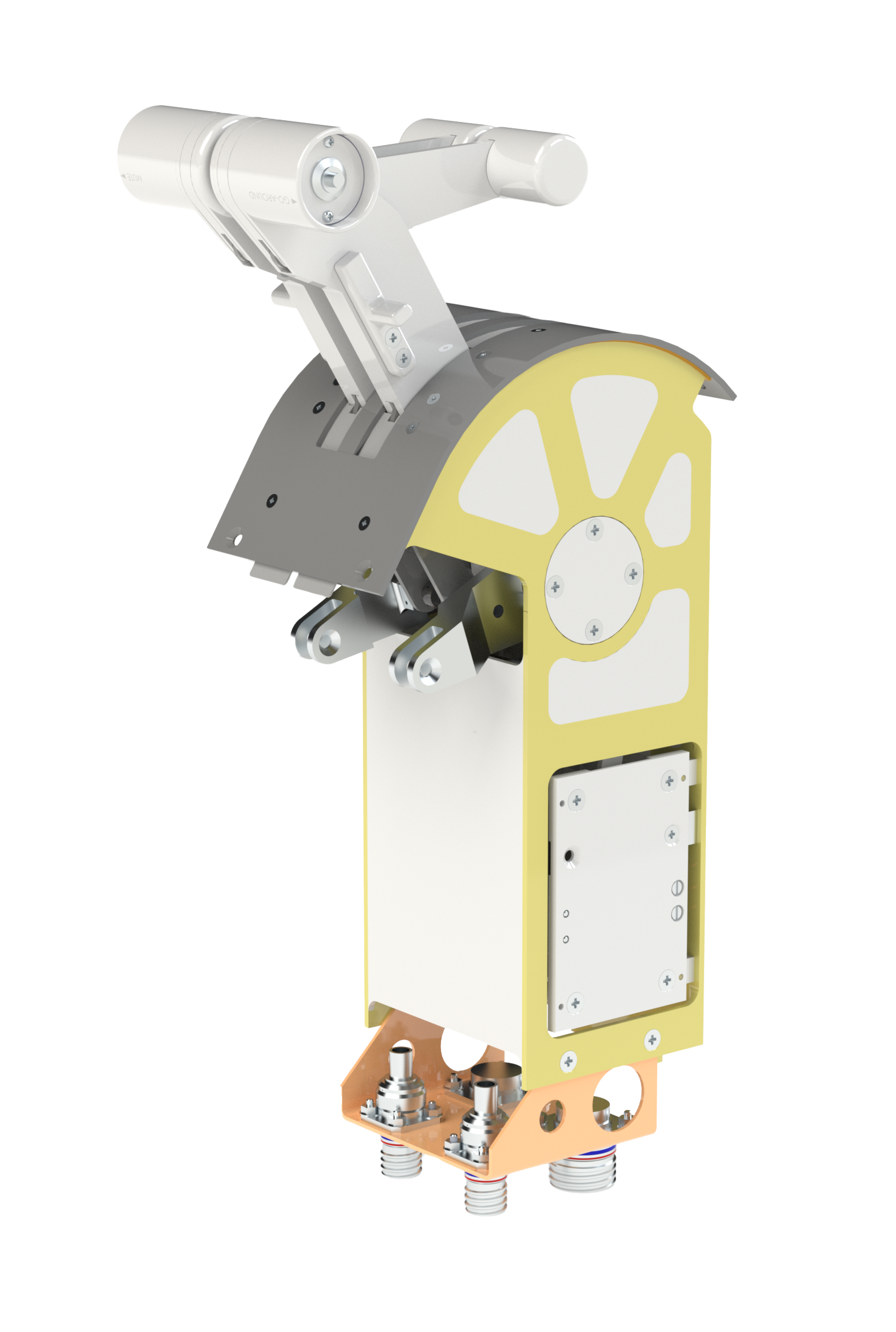

Throttle Quadrants

We tailor the design and testing of our throttle quadrants to suit each unique application. Over the years, we've provided custom aircraft throttle quadrants for a wide range of aircraft, including commuter aircraft, executive aircraft, helicopters, and specialized applications such as the US Navy PHM, Boeing Jet Foil, US Navy LCAC, and USMC LVTP-7 gear section quadrant.

tailored with precision

Our aircraft throttle quadrants are tailored with precision for any aircraft application.

Ergonomics

- Knob size (shape fairly standard per FARs)

- Go-around switch location

- Friction (wheel, lever, or constant, materials)

- Detent type (lift buttons/knobs, lift lever, push to side) to side)

- Power/condition lever length

- Reverse method ((T/R or reverse ppp)rop.)

- Visual position indicators (engraving, edge-lighted panel – NVG compatible)

Durability

- Housing (typically rubber mold casting) strength to provide mounting/load path for all components

- Levers (machined, square tube)

- Knob material properties (Typically composite Molded or Knob material properties (Typically composite. Molded or machined. Good thermal properties, degradation resistant, Material strength for mounting inserts and constant use)

- Switch selection criteria (cycles rating contact type) Switch selection criteria cycles, rating, contact type)

- Switch bank actuation mechanism

- RVDT/Potentiometer life

- Friction material life

Output

- Mechanical through clevis to push-pull rods or cables (must maximize mechanical advantage and minimize system friction)

- Electro-mechanical (switch banks for discreet position signals, not FBW) through rods, cables and connectors

- FBW w/ Mechanical Back-up (must synchronize) mechanical output and electronic signal)

- FBW – Potentiometers, RVDTs. (Must consider Potentiometers, RVDTs. (Must consider tolerances, application, redundancy)

Reliability & Maintainability

- Past design experience used to meet customer specifications.

- MTBF, MTBUR MTBUR

- Met by choice of materials, switches and design/interface of dynamic components

- Plug & Play TQA for easy installation/rigging/removal

- Optimize on previous design experience Optimize on previous design experience

- Modular assembly

- Minimize need for special tools

- ATP equipment specific to product

Weight

- Always a balance between operational requirements functional requirements and requirements, functional requirements and environmental requirements

- Goal is maximum strength minimum weight Goal is maximum strength, minimum weight

- Some flexibility with castings (style, wall-thickness) and materials

Environmental Considerations

- Military (stringent for operational exposure)

- Commercial (stringent for dispatch rate)

- General Aviation (stringent for dispatch rate)

- Helicopter (vibration)

- Installation location

- Protected cockpit Protected cockpit

- Will not be used as a step?

Throttle Quadrant Benefits/Applications

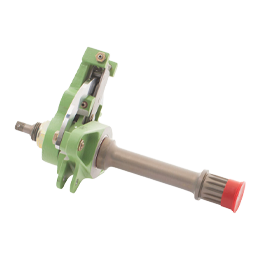

Mechanical

In our mechanical throttle quadrants, precision engineering meets robust construction to provide tactile control and responsiveness for critical flight applications, ensuring safety and performance.

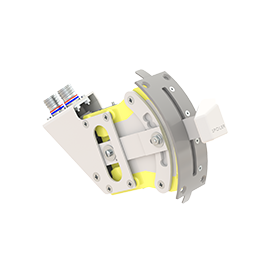

Electro-mechanical

Our electro-mechanical throttle quadrants seamlessly integrate electronic precision with mechanical reliability, offering advanced fly-by-wire control systems to meet the most demanding aviation requirements.

FBW with Mechanical Back-up

Our FBW (Fly-By-Wire) with mechanical back-up throttle quadrants combine cutting-edge electronic control with robust mechanical systems, ensuring aircraft safety and performance even in emergency situations.

Completely FBW

Our completely FBW (Fly-By-Wire) throttle quadrants represent the pinnacle of modern aircraft control, providing precise, reliable, and highly responsive performance, enhancing the flight experience and pilot confidence.